| Sustainable Development Goals |

Positive and Negative Impacts

Sustainable supply chain management involves a comprehensive approach to overseeing every stage of the supply chain—upstream, midstream, and downstream. This goes beyond focusing solely on economic gains and includes the critical consideration of social and environmental impacts. Such an approach is vital not only for the long-term sustainability of the organization but also for ensuring a positive future for humanity and future generations.

PTT recognizes the importance of sustainable supply chain management and is dedicated to integrating sustainability principles throughout its operations. As part of this commitment, PTT applies the framework of Environmental, Social, and Governance (ESG) standards in its procurement and vendor management processes. This approach fosters “Sustainable Supply Chain Management,” which serves as a comprehensive risk management strategy, drives business opportunities, and contributes to building the capabilities of partners. By doing so, PTT is well-positioned to adapt to rapidly changing global dynamics, ensuring mutual business growth in a sustainable manner. Additionally, this strategy guarantees reliable product delivery and services in line with customer demands (Supply Reliability).

Objectives/ Goals

| Plan | 2024 Targets | 2024 Performance | Long-term Targets |

|---|---|---|---|

| Evaluation of sustainable practices for vendors in the critical/ strategic group within the area |

100% of targeted critical/strategic suppliers have undergone evaluation for other products and services. |

A total of 21 suppliers in the critical/ strategic group were assessed for other products and services, representing 100% of the targeted suppliers. |

Up to 80% of critical/ strategic suppliers have successfully developed their practices and operate their businesses sustainably. |

| Sustainable procurement management in accordance with ISO 20400 standards |

Integrating sustainability into the joint procurement process across PTT Group companies following the sustainable procurement guidelines (ISO 20400) for at least 3 items. |

Integrated sustainability into the joint procurement process across PTT Group companies following the sustainable procurement guidelines (ISO 20400) for 3 items, including: |

Engaging in the joint procurement process across PTT Group companies following the sustainable procurement guidelines (ISO 20400) and being aligned with the defined action plans. |

| Collaborative procurement of goods and services within the PTT Group | Collaborating with companies within the PTT Group to procure goods and services, aiming for a 7% value-added increase in total expenditure. | Collaborated with companies within the PTT Group to procure goods and services, aiming for a 12.95% value-added increase in total expenditure. | Collaborating with companies within the PTT Group to procure goods and services, aiming for a 10-12% value-added increase in total expenditure. |

| Supplier satisfaction with PTT’s operational direction communication to foster a clear understanding of PTT’s operations and procurement processes through supplier seminars. | Satisfaction score of 4.5 out of 5.0. | Satisfaction score of 4.83 out of 5.0. | Satisfaction score of 4.5 out of 5.0. |

Management ApproachGRI414-1

Governance Structure

PTT prioritizes the execution of procurement endeavors that are not only cost-effective, but also characterized by transparency, efficiency, and accountability, thereby fostering trust among all stakeholders. To ensure adherence to legal frameworks, regulations, guidelines, and operational procedures governing both material and non-hydrocarbon commercial procurement, PTT has instituted the PTT Procurement Management Audit Committees. The committees also provide consultation on appropriate procurement and contracting processes, fostering knowledge exchange within the organization and affiliated companies abroad. This collaboration leads to enhanced efficiency in improving procurement and contracting processes, with EVP, Organization Effectiveness, serving as the chairman of both committees.

In addition, PTT has appointed a Vendor Selection Committee to manage the creation and maintenance of the PTT Approved Vendor List (PTT AVL). This list supports the procurement of goods and services through a competitive bidding process, ensuring that vendors are selected based on rigorous criteria. The goal is to identify efficient vendors capable of fulfilling the organization’s needs while fostering long-term, sustainable partnerships with PTT.

PTT Group Procurement Policy

PTT announced the PTT Group Procurement Policy on May 28, 2025, signed by the CEO and President of PTT, to establish a unified framework for procurement activities across all companies within the PTT Group. The Assistant Managing Director of PTT is tasked with reporting procurement performance to the Corporate Governance and Sustainability Committee. Additionally, risks related to the supply chain are reported and monitored by the Risk Management Committee at the board level.

In line with its commitment to sustainability, PTT has incorporated sustainable procurement practices into its strategy, with the following key principles:

- Local Sourcing: PTT actively supports sourcing goods and services from local suppliers (with “local” referring to within Thailand (Significant Location)). The Company encourages sourcing from regions where its operations are based, thereby boosting the local economy, creating jobs, and generating income for local communities. This approach not only offers cost advantages and faster transportation but also reflects PTT's commitment to building long-term, mutually beneficial relationships with the communities in which it operates. As a result, PTT earns the trust of local communities and fosters goodwill. Furthermore, PTT encourages its suppliers to be socially responsible and to engage in local sourcing, contributing to lower product costs.

PTT Group’s Procurement Policy

PTT Supplier Sustainable Policy and Code of Conduct

PTT places a high priority on sustainable supply chain management and is committed to translating this into tangible actions through effective oversight of its suppliers. To achieve this, PTT has established the PTT Supplier Sustainable Code of Conduct (SSCoC), which applies to suppliers entering into contracts with PTT for transactions valued at 2 million baht or more and/or work that may have an impact on safety, occupational health, or the environment. It also applies to suppliers seeking to be registered with PTT. The SSCoC includes key sustainability requirements across four main areas:

- Business Integrity

- Corporate Social Responsibility

- Safety

- Environmental Management

PTT Group’s Sustainable Supplier Procurement and Management Policy

PTT Supplier Sustainable Code of Conduct

Operational Processes

Supply Chain Management at Corporate Level

- Supplier Selection and Awarding

PTT upholds high standards for selecting, evaluating, and auditing suppliers with fairness and transparency. The evaluation is based on business sustainability principles, supplier reliability, and their capacity to meet PTT’s specific needs. Regarding supplier selection process, PTT has established pre-qualification of Approved Vendor List, where assessment scores include a minimum weight to ESG criteria, such as Safety, Health and Environmental Data. Suppliers must meet qualifications related to ESG criteria. Those suppliers with better ESG performance are preferred by applying a minimum weight to ESG criteria in supplier selection and contract awarding. Additionally, suppliers will be excluded from contracting in case they cannot achieve minimum ESG requirements within a set timeframe. PTT maintains an “Approved Vendor List (AVL)” to identify qualified suppliers for collaboration. Suppliers are assessed using a comprehensive questionnaire, evaluating their commercial qualifications, technical expertise, quality standards, service readiness, production capacity, logistics, safety measures, occupational health practices, environmental compliance, and adherence to industry standards. Suppliers must demonstrate the ability to operate in alignment with PTT's Sustainable Supplier Code of Conduct. Suppliers that meet the set criteria will be approved for inclusion in the AVL. The management of the AVL is overseen by the Supplier Selection Committee and the Vendor List Working Group. In addition, PTT has incorporated specific requirements for all procurement activities to ensure that suppliers consistently adhere to the sustainable practices outlined in the PTT Supplier Sustainable Code of Conduct.

- Supplier Screening

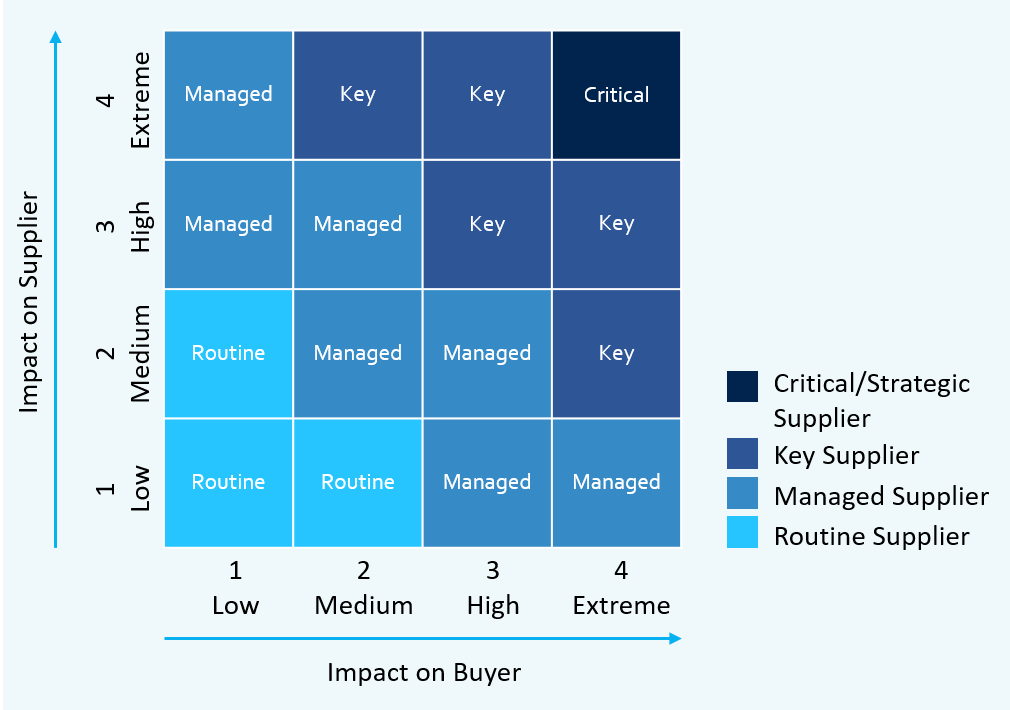

PTT has structured its supplier registry to ensure a robust risk management approach, aligning with sustainable procurement standards while safeguarding against potential disruptions to its business operations. The Company conducts a comprehensive risk assessment of key suppliers using a four-level evaluation framework across two primary dimensions:

1. Sustainability Risk: This risk is assessed by considering various factors, including country-specific risks, and/or sector-specific risks, and/or commodity-specific risks. The sustainability risks are evaluated in the following areas:

1.1 Quality: Potential delays in projects and the ability to meet required quality standards for goods or services.

1.2 Environmental: Management of air pollution, greenhouse gas emissions, water and wastewater treatment, waste management, and energy usage.

1.3 Governance: Anti-corruption practices and commitment to fair competition.

1.4 Social: Labor relations, human rights, and workplace safety.

2. Supply Risk: This is assessed based on the criticality of goods or services to PTT's operations. For example, this includes items with high order volumes, products or services that are vital for operations, or goods that are irreplaceable.

Supplier Screening Criteria

|

PTT utilizes the results of risk assessments to develop management strategies for suppliers, tailored to their level of importance, as outlined below:

| Management Level for Suppliers | Definition | Management Strategies | Management Tools |

|---|---|---|---|

| 1. Critical/ Strategic Supplier | This group comprises suppliers with operations that pose a significant risk of severe impacts, both on the suppliers themselves and on the surrounding communities. These impacts can result in major consequences for the buyer, affecting both business operations and corporate reputation. |

Foster long-term business relationships and synergies to strengthen joint business capabilities and create added value. |

|

| 2. Key Supplier | This group includes suppliers whose products directly reach consumers. The potential for high impact on the buyer’s business and corporate image is substantial. | Develop long-term relationships to manage expenses/risks and maintain competitiveness. |

|

| 3. Managed/ Routine Supplier | This group includes suppliers whose operations are mostly operational in nature, with potential impacts on nearby communities or surrounding areas. The associated risks to the buyer are generally considered low to moderate. | Maintain relationships based on performance and manage expenses and risks according to customer requirements. |

|

- Supplier Performance Evaluation and Sustainability Assessment (Supplier Assessment)

PTT has established a comprehensive process for evaluating and monitoring the sustainability performance of its suppliers, co-developed as part of a multi-stakeholder initiative by PTT and the company’s subsidiaries in the oil, gas, and petroleum industry. This includes setting clear criteria and standards for assessment, which are aligned with national regulations such as labor laws, environmental laws, safety regulations, and international management standards like ISO 9001, ISO 14001, ISO37001, ISO26000, ISO 45001, SA 8000, AA1000, and OHSAS 18001. Additionally, the process ensures compliance with anti-corruption policies. Each year, PTT’s ESG auditors follow the ISO 19011:2018 auditing standards to assess and evaluate suppliers, focusing on critical/strategic suppliers every three years. The evaluation process is structured as follows:

- Desk Assessment

PTT has a process for verifying the ESG data of its suppliers through a sustainability assessment form. Suppliers seeking registration in critical work groups (Approved Vendor List) or those involved in high-risk activities, or categorized under strategic/critical work groups, are required to submit performance data related to the assessment topics. These topics cover four key areas: business integrity, human rights, labor relations, workplace health and safety, and environmental management systems. The submitted data is reviewed by PTT’s ESG team to evaluate sustainability performance. If the assessment identifies significant operational risks, PTT reserves the right to conduct an on-site assessment to validate the results of the evaluation. - On-site Assessment

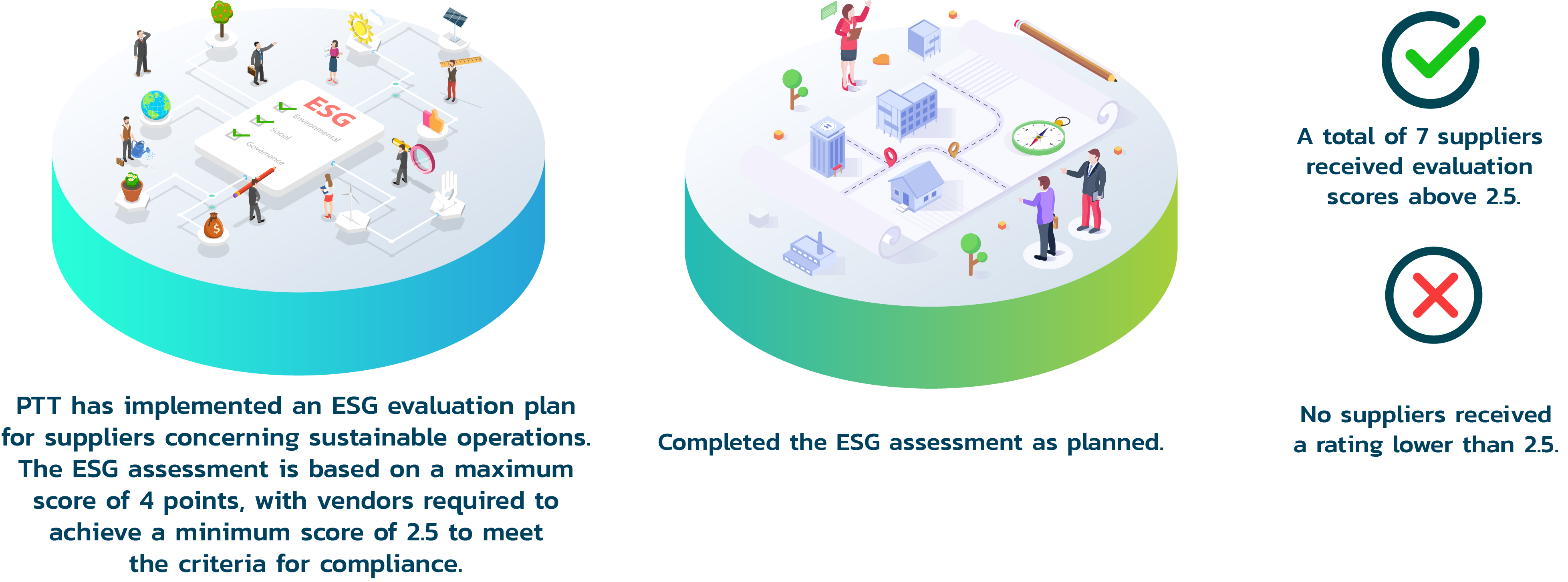

For suppliers who have undergone a desk assessment and are still found to have high sustainability risks, PTT has developed an additional method for evaluating their sustainability performance on-site. This is carried out using a sustainability capability assessment form, which aligns with international standards and principles (ISO 45001, ISO 14001, and ISO 9001). The process also involves reputable, accredited external auditors (3rd Party Assessment) to conduct the evaluation. Suppliers must achieve a score of at least 2.5 out of 4 to pass the assessment. If a supplier’s score is below the required threshold, they must create a Corrective Action Plan (CAP) to address and improve their operations.

- Providing Guidance and Monitoring Corrective Action Plans

Suppliers who have been assessed and are still found to have high risks must submit an improvement plan to PTT for review and ongoing monitoring. PTT will provide continuous recommendations to enhance operational capabilities in alignment with the Corrective Action Plan (CAP), both through online channels and on-site at the supplier's premises. If the supplier fails to improve their performance within the specified time frame, the contract may be subject to termination in accordance with the terms outlined in the Supplier Code of Conduct.

- Third-party supplier assessment for the trading of bio-feedstock and biofuels

PTT international trading PTE Ltd (PTTT) has received third-party accreditation as a sustainable trader of bio-feedstock and biofuel from the ISCC EU (International Sustainability and Carbon Certification) and ISCC PLUS (International Sustainability and Carbon Certification). These supplier assessments were conducted via desk and onsite assessment to ensure compliance with recognized industry standards across the whole value chain by Control Union Certifications B.V. Zwolle - an organization accredited by The Dutch Accreditation Council RvA.

To comply with ISCC System requirements, all products traded along the value chain must be traceable and have a Document of Sustainability Declaration (SD). The Sustainability Declaration contains relevant information about the sustainable material including the GHG emission calculation that must be issued by the supplier for each product delivery. Suppliers of PTTT’s Sustainable Material must be Certified by the ISCC and retain a Valid Certification which can be checked online on the ISCC website.

PTT also conducts second party supply assessment through desk research and onsite visits by checking the validity of ISCC certifications and visiting suppliers’ plants, storage areas, and related logistic facilities.

- Supplier Capacity Development and Relationship Management

PTT places great emphasis on developing supplier capabilities to encourage learning and promote sustainable business practices. This is achieved by establishing a structured development framework through the following initiatives:

Activities

Objectives

Annual Partner Seminars

These seminars are designed to communicate PTT's policies, business direction, and operational strategies while providing a platform for open dialogue and the exchange of information and feedback between suppliers and PTT. In addition, supplier satisfaction surveys are conducted after each procurement process and upon completion of contract management. The feedback collected is used to continuously improve and streamline the procurement processes.

Sustainability Capacity Building Program for Suppliers

This program focuses on imparting technical knowledge to suppliers on reducing environmental, social, and governance (ESG) impacts associated with their business operations over the long term. The goal is to equip suppliers with the theoretical knowledge necessary to apply sustainable practices in their operations, reduce risks, and create opportunities for long-term business sustainability. For example, the Green Industry project, which encourages suppliers with a valid manufacturing license (RorNgor. 4) to apply for Green Industry Level 2 certification.

Additionally, PTT places great emphasis on managing payment timelines to suppliers according to the specific terms outlined in each procurement contract. This ensures that there is no adverse impact on the financial liquidity of both the suppliers and PTT. Payment periods are determined based on internationally accepted standards for each type of business, taking into account costs, financial risks such as exchange rate fluctuations, and maintaining fairness to all partners.

- Strengthening Procurement Staff Capabilities

PTT and its affiliates conduct annual reviews and development plans for procurement officers to enhance their ability to manage a sustainable supply chain effectively. This allows them to respond to organizational changes with efficiency. These efforts include training programs, communication initiatives, and knowledge management practices, ensuring that employees are well-equipped to integrate information technology with procurement processes. This is facilitated through the Digital Procurement system, developed by PTT to ensure a streamlined, flexible, and efficient procurement process, which ultimately improves employee performance and organizational effectiveness. - Advancing the Digital Procurement System

PTT leverages modern and appropriate technology to enhance procurement processes, ensuring agility, transparency, and standardized practices across the organization. Various systems have been developed to support procurement activities for PTT employees, including the PTT Procurement Planning System for annual procurement scheduling and the PTT Smart Procurement System for electronic procurement. Additionally, PTT provides systems and websites to support supplier engagement in procurement activities, including the PTT Procurement Website for procurement announcements, the PTT Bid Submission platform for submitting bids and requests for documents online, and the PTT e-Bank Guarantee system. - Enhancing Transparency Across the Supply Chain

PTT publishes its procurement data monthly to ensure easy access for the public, aligning with its strategy of Transparency & Sustainability to uphold transparency as an organization. PTT complies with the Government Information Commission's announcement, which mandates that procurement decision data be made available to the public under Section 9 (8) of the Official Information Act, B.E. 2540 (A.D. 1997). Furthermore, PTT has signed a memorandum of understanding (MOU) on anti-corruption efforts with the National Anti-Corruption Commission (NACC), the State Enterprise Policy Office (SEPO), and state-owned enterprises. This collaboration aims to support the national strategy for combating corruption and successfully implement anti-corruption measures, government policies, and the anti-corruption action plan. Additionally, PTT submits procurement projects valued at 1 billion baht or more, or construction projects with a budget of 500 million baht or more, to the Comptroller General’s Department for consideration in the anti-corruption public procurement initiative. PTT also participates in the Integrity Pact, in accordance with the guidelines set by the Anti-Corruption Cooperation Committee (ACC), further demonstrating its commitment to transparency in its operations.

Supply Chain Management at the Business Level

PTT has developed a strategy for managing the supply chain of natural gas and liquefied petroleum gas (LPG), with a strong focus on delivering the right quality and quantity efficiently, safely, and in an environmentally friendly manner. The strategy ensures transparency and accountability across operations, both within PTT and with its suppliers. Additionally, it aims to foster value creation throughout the PTT Group, enhancing the overall supply chain for natural gas and LPG.

- Natural Gas (NG) Procurement Process The process for procuring natural gas at PTT consists of six key steps:

- Define procurement details and requirements that align with customer needs, legal obligations, regulations for the use or connection of gas pipeline systems, and PTT’s internal guidelines.

- Supplier/ partner selection is based on PTT's evaluation criteria, applicable regulations, strategic objectives, as well as the overall performance and capabilities of the suppliers/ partners.

- Communicate procurement requirements and guidelines, including negotiations and the drafting of natural gas sales contracts with gas suppliers/ partners.

- Manage the operations of suppliers/ partners through effective oversight of natural gas sales contracts.

- Foster supplier/ partner development by facilitating knowledge exchange through monthly operation meetings, training, and seminars. These interactions aim to improve communication and address customer expectations, complaints, gas quality issues, and instances of gas quantity deliveries not meeting contract terms, in order to make improvements that better align with customer needs.

- Conduct regular assessments of each delivery, evaluating supplier/partner service capabilities monthly. Suppliers/v partners will be required to make improvements if performance falls below standards or abnormalities are detected. Additionally, reliability assessments from the previous year will inform the development of future natural gas procurement plans and contingency strategies for cases where suppliers/ partners are unable to fulfill deliveries.

- PTT's Procurement of Liquefied Natural Gas (LNG) is conducted in two main forms: long-term, medium-term, and short-term contracts, as well as spot LNG purchases in the spot market. The procurement process considers factors such as volume and customer demand, along with various relevant requirements, including legal regulations, third-party access (TPA) codes for LNG station services, and PTT’s internal policies and guidelines. The selection of partners is based on PTT’s established evaluation criteria, which assess both the performance and overall capabilities of potential partners. Once selected, negotiations are held, and contracts are finalized. PTT closely manages partner operations through contract administration, ensuring alignment with the Company’s strategic objectives and mission. To meet PTT’s goals, the LNG procurement process also takes into account the country’s energy security and the anticipated impact of the liberalization of the LNG business, which will drive increased competition. As a result, PTT must effectively manage procurement risks and carefully plan its LNG portfolio to ensure competitive costs. This approach involves a combination of long-term, medium-term, short-term contracts, and spot LNG purchases to meet the country’s evolving LNG demand.

Supply Chain Risk Management within the PTT Group

To manage supply chain risks, PTT Group follows the emergency response plan and crisis management plan alongside a Business Continuity Management (BCM) plan. These measures are managed through the Emergency and Crisis Management Center, with annual BCM drills conducted jointly with both internal and external organizations. The process includes post-incident management and the restoration of normal operations. Additionally, the BCM plan is regularly reviewed and monitored by external agencies to ensure its effectiveness and alignment with evolving circumstances. To mitigate risks and address potential energy shortages, PTT collaborates with the Ministry of Energy in annual emergency response drills.

PerformanceGRI 3-3

Policy Compliance

Sustainable Procurement

In 2024, PTT adopted the ISO 20400:2017 standard for sustainable procurement in three additional categories across the PTT Group. The plan is to expand this approach to cover all categories within the next five years. Furthermore, there are 33 projects related to environmentally friendly procurement, totaling a procurement value of 449 million baht. The performance of local sourcing can be referenced in the table below.

Local product and service procurement (%) GRI 204-1

|

Supply Chain Management at Corporate Level

Supplier Selection and Awarding

In 2024, a total of 337 suppliers from 28 different categories were approved for inclusion in the PTT Supplier List. The breakdown of suppliers selected based on sustainability criteria is as follows:

|

100% of new suppliers have been selected based on the ESG Assessment Criteria. |

|

that have entered into contracts with PTT. |

100% of suppliers entering into contracts with PTT valued at 2 million baht or more, and/or those involved in work that could impact safety and the environment, as well as suppliers wishing to register with PTT, have signed an acknowledgment and committed to adhering to PTT’s Supplier Sustainability Code of Conduct. |

1. KPIs for Supplier Screening

Type of Information |

Performance |

| 1.1 Total number of Tier-1 suppliers | 1,940 |

| 1.2 Total number of significant suppliers in Tier-1 | 7 |

| 1.3 Percentage of total spend on significant suppliers in Tier-1 | 0.45 % |

| 1.4 Total number of significant suppliers in non Tier-1 | 14 |

| 1.5 Total number of significant suppliers (Tier-1 and non Tier-1) | 21 |

Remarks:

• Tier-1 Suppliers are suppliers and contractors who hold direct procurement contracts with PTT through a formal procurement process for non-hydrocarbon materials and goods.

• Significant suppliers in Tier-1 are primary suppliers are primary suppliers and contractors with whom PTT aims to establish long-term business relationships. These partners play a key role in enhancing collaborative business capabilities and generating added value. They are high-risk entities whose operations could have severe repercussions not only on themselves and PTT but also on the surrounding communities, potentially causing significant disruptions to both business operations and corporate reputation.

• Significant suppliers in non Tier-1 are suppliers and contractors who do not have direct purchase contracts with PTT but are indirectly connected as vendors or service providers. These partners manage high-risk operations that could have a significant impact on Tier-1 key suppliers.

Example of Managing High ESG Risk Suppliers: Road Transport Suppliers of Petroleum Products

PTT has established strict safety standards and management systems to ensure transport operators adhere to these regulations. The following measures are in place:

- PTT collaborates with the State Railway of Thailand to review and align rail transportation safety standards with international regulations, specifically the Regulation Concerning the International Carriage of Dangerous Goods by Rail (RID).

- PTT develops the Advanced Analytics for Road Safety System to analyze and predict risks related to accidents during transportation. It integrates data from three main sources: driver behavior, maintenance records, including breakdowns and accident histories, and transport routes, including identified high-risk areas. By processing this data, PTT can identify potential risks and implement corrective or preventive actions. Furthermore, PTT promotes the adoption of the Marine Terminal Information System (MTIS) across its network, ensuring that safety best practices are shared across the PTT Group. This is achieved through the PTT Group Transportation Safety Management Taskforce.

- PTT organizes Risk in Road Safety initiatives to enhance safety awareness among drivers transporting petroleum products. The process involves:

- Drivers reporting risk-prone areas along their routes, identifying hazards they may encounter.

- PTT assesses the severity of these reported risks, considering accident data from the identified areas. If the risk is deemed high, PTT will conduct an on-site risk assessment.

- Risk assessment results are used to implement corrective measures, mitigate risks, or establish preventive measures, especially in areas with high risk.

- PTT communicates the identified risks to contractors through the Transportation Safety Management Taskforce, rewarding companies and drivers who adhere to safety guidelines. In 2024, 532 participants joined the program, reporting 1,163 potential risk points, which were stored in the database and shared during safety meetings within the PTT Group.

- PTT, in collaboration with PTT Exploration and Production Public Company Limited (PTTEP), the State Railway of Thailand (SRT), community leaders, and government agencies from Phitsanulok Province, conducted a comprehensive emergency response and crisis management drill. The scenario simulated a train derailment while towing crude oil tanker cars at the Bueng Phra Oil Depot in Muang District, Phitsanulok. The drill was designed to enhance preparedness and ensure proper emergency protocols are followed by employees, contractors, local community members, and government authorities.

- The PTT Group organized a meeting of its Petroleum Product Marine Transport Safety Taskforce to define strategic objectives and operational direction for the safe transport of petroleum products. This meeting involved stakeholders across the PTT Group and transportation contractors, covering key aspects such as legal compliance, organizational management, the handling of aging assets, employee capability building for office, port, and ship personnel, and the promotion of a safety-first culture among management and employees of all levels. The ultimate goal is to eliminate accidents in the transportation of petroleum products via maritime routes.

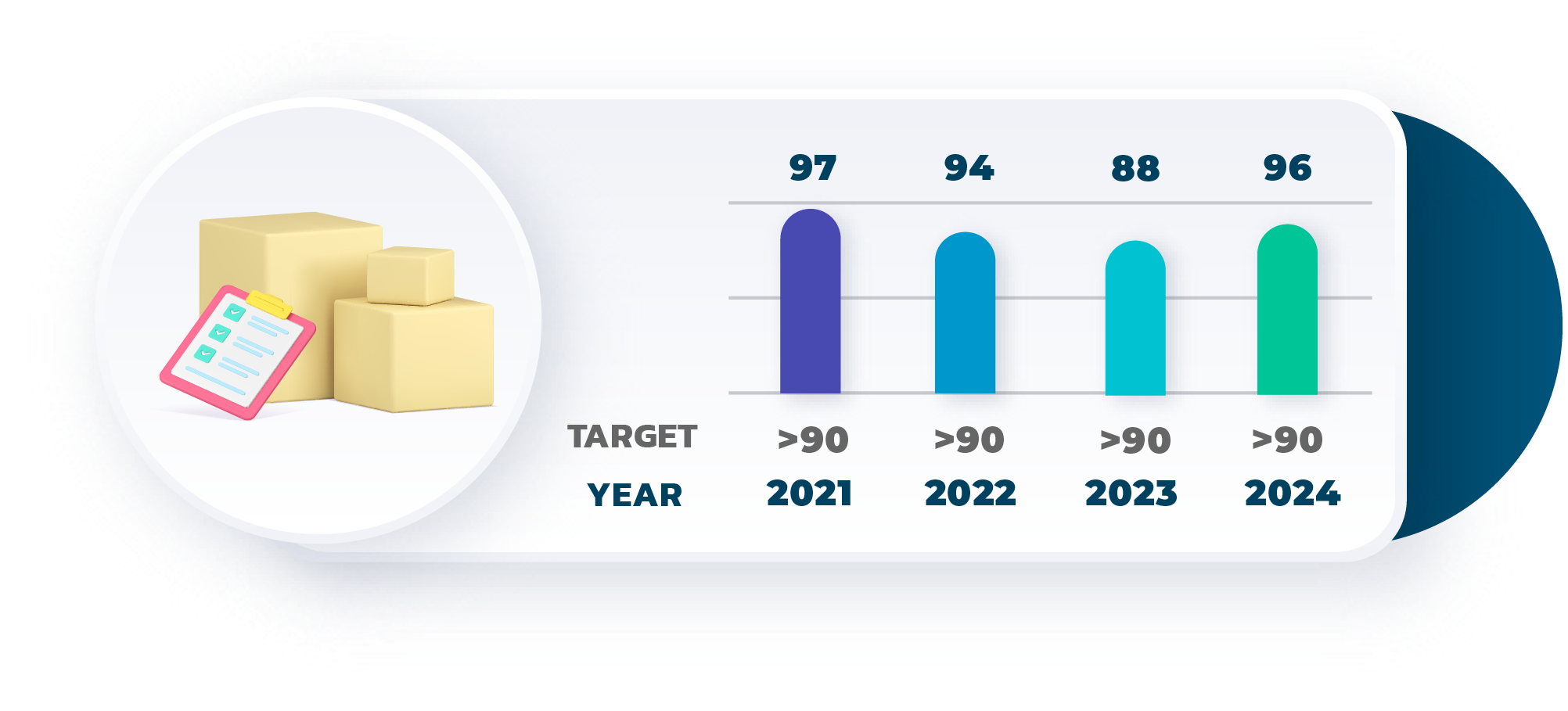

2. Sustainable Supplier Performance Assessment (KPIs for Supplier Evaluation)

Type of Information |

2024

|

2024 Targets |

| Total number of suppliers assessed via desk assessments/on-site assessments | 21 | 100 % |

| % of unique significant suppliers assessed | 100 % | |

| Number of suppliers assessed with substantial actual/potential negative impacts | 0 | |

| % of suppliers with substantial actual/potential negative impacts with agreed corrective action/improvement plan | 0 | |

| Number of suppliers with substantial actual/potential negative impacts that were terminated | 0 | |

| Total number of suppliers supported in corrective action plan implementation | 0 | |

| % of suppliers assessed with substantial actual/potential negative impacts supported in corrective action plan implementation | 0 | |

| Total number of suppliers in capacity building programs | 21 | 100 % |

| % of unique significant suppliers in capacity building programs | 100% |

Performance Assessment has been reported and are obtained third-party verification in accordance with GRI Reporting Standards number 308-2 Negative environmental impacts in the supply chain and actions taken (2016) and 414-2 Negative social impacts in the supply chain and actions taken (2016). Please see Assurance Statement.

Based on the suppliers’ sustainability assessment, PTT suggests as follows:

Environmental (E) |

Suggestions and Improvements from the Evaluation |

|---|---|

| Environmental Management |

|

Social (S)

|

Suggestions and Improvements from the Evaluation |

|

Safety, Occupational Health in Workplace |

|

|

Human Capital, Community, and Social Development |

|

|

Labor Management and Human Rights |

|

Governance (G) |

Suggestions and Improvements from the Evaluation |

|

Compliance with Laws and Regulations |

|

|

Responsible Procurement |

|

|

Remarks:

The ESG evaluation criteria for vendors involved in sustainable operations are scored on a scale of 4 points. Vendors must score at least 2.5 to be considered compliant.

3. Enhancing Supplier Capability and Relationship Management

In 2024, PTT held five supplier seminars at various locations: two at the headquarters, one at the Rayong Natural Gas Separation Plant, one at the Natural Gas Pipeline Division, and one at the Natural Gas for Vehicles Division. These seminars highlighted PTT's business direction towards achieving Net Zero by 2050 under its new vision and mission, as well as its sustainability efforts, corporate governance practices, stakeholder management, the Approved Vendor List (AVL), and the adoption of the Digital Procurement system aimed at improving transparency, convenience, and efficiency. Suppliers were also encouraged to pledge their commitment to anti-corruption through the CAC initiative. Furthermore, PTT organized training as part of the PTT Supplier Sustainability Capacity Building Program, which incorporated human rights considerations into the curriculum. All suppliers participating in the program, representing 100% of those involved, successfully completed the training.

Following these activities to enhance supplier relationships and capabilities, PTT conducted a supplier satisfaction survey, and the results are as follows:

|

Employee Capability Development and Supplier Relationship Management

PTT organizes a variety of training programs, such as workshops focused on implementing sustainable procurement practices aligned with the ISO 20400:2017 Sustainable Procurement standards. These sessions aim to equip procurement officers with the skills and knowledge necessary to carry out sustainable procurement effectively. Additionally, PTT has developed a training program for PTT Group ESG Auditors, who assess the sustainability performance of suppliers. The Company also offers Human Rights training (Introduction to Human Rights) to ensure employees understand the criteria for evaluating supplier sustainability through the PTT Group ESG Questionnaire. This training covers the fundamental principles of auditing, including best practices and processes to become a proficient auditor, allowing employees to effectively integrate these insights into the supplier assessment process and promote sustainable business operations. Moreover, PTT offers additional courses for all employees, including those on public procurement law and government supply management, as well as training on commercial procurement practices. To further enhance knowledge, PTT invites experienced professionals from government agencies, such as experts from the Comptroller General’s Department and the Office of the Attorney General, to provide lectures and share practical advice, ensuring that employees acquire the expertise needed to perform procurement tasks efficiently and effectively.

Digital Procurement System Development

Last year, PTT improved its PTT Vendor Management (PTTVM) system by adding a function that allows for the assessment of suppliers' performance post-delivery. The evaluation results, along with detailed assessment topics, are now displayed within the PTTVM system and compiled into reports for suppliers to review. This process enables suppliers to receive feedback and recommendations for improvement, helping them to enhance their operations for future projects.

Supply Chain Transparency

PTT was awarded an honorable mention for the Organization of Transparency at the 11th Annual Awards by the National Anti-Corruption Commission (NACC) in 2023.

Supply Chain Risk Management within PTT Group

In 2024, PTT participated in a cybersecurity capability exercise organized by the National Cybersecurity Agency (NCSA) to assess and strengthen its ability to address cyber threats. This exercise targeted government agencies, regulatory bodies, Critical Information Infrastructure (CII) organizations, Sectoral CERTs, and ThaiCERT. The simulated scenario involved a cyber-attack on the energy and utilities sector, where attackers implanted a Remote Access Trojan (RAT) malware on both server and user devices within multiple organizations. This allowed attackers to take control of the SCADA system, severely disrupting critical services and causing significant service outages at both the organizational and national levels.

In addition, PTT took part in an energy crisis response tabletop exercise with the Ministry of Energy, the Electricity Generating Authority of Thailand (EGAT), and other relevant agencies. The simulation focused on a potential disruption in the Strait of Hormuz, caused by the ongoing conflict between Israel and Hamas, which could block the transport of oil and liquefied natural gas from Qatar to Thailand. The exercise aimed to ensure readiness and strengthen the integrated response for maintaining the country’s energy security during critical situations.