| SDG Support |

Positive and Negative Impacts

Impact of Issues over Time

ShortTerm |

MediumTerm |

Long

|

High |

High |

High |

|

Financial Materiality |

Impact Materiality |

|

| Risks | Opportunities | ||

| - Rising insurance and healthcare costs - Financial and reputational damage |

+ Increase productivity and enhance business competitiveness | + Reduce accident, illness, and injury rates at the workplace + Improve the quality of life for employees, contractors, and the surrounding community - Injuries and illnesses from work-related accidents involving employees and contractors - Hazards and risks from accidents/emergencies during construction projects and operations affecting surrounding communities |

|

Management Overview

PTT manages security, safety, and occupational health within the framework of Security, Safety, Occupational Health, and Environmental Management (SSHE). This approach is integrated into the Company’s broader Quality, Security, Safety, Occupational Health, and Environmental Management (QSHE) system. Detailed information about the management framework, policies, governance structure, and management systems is available on the website under the section titled SSHE Management System.

Objectives/ Targets

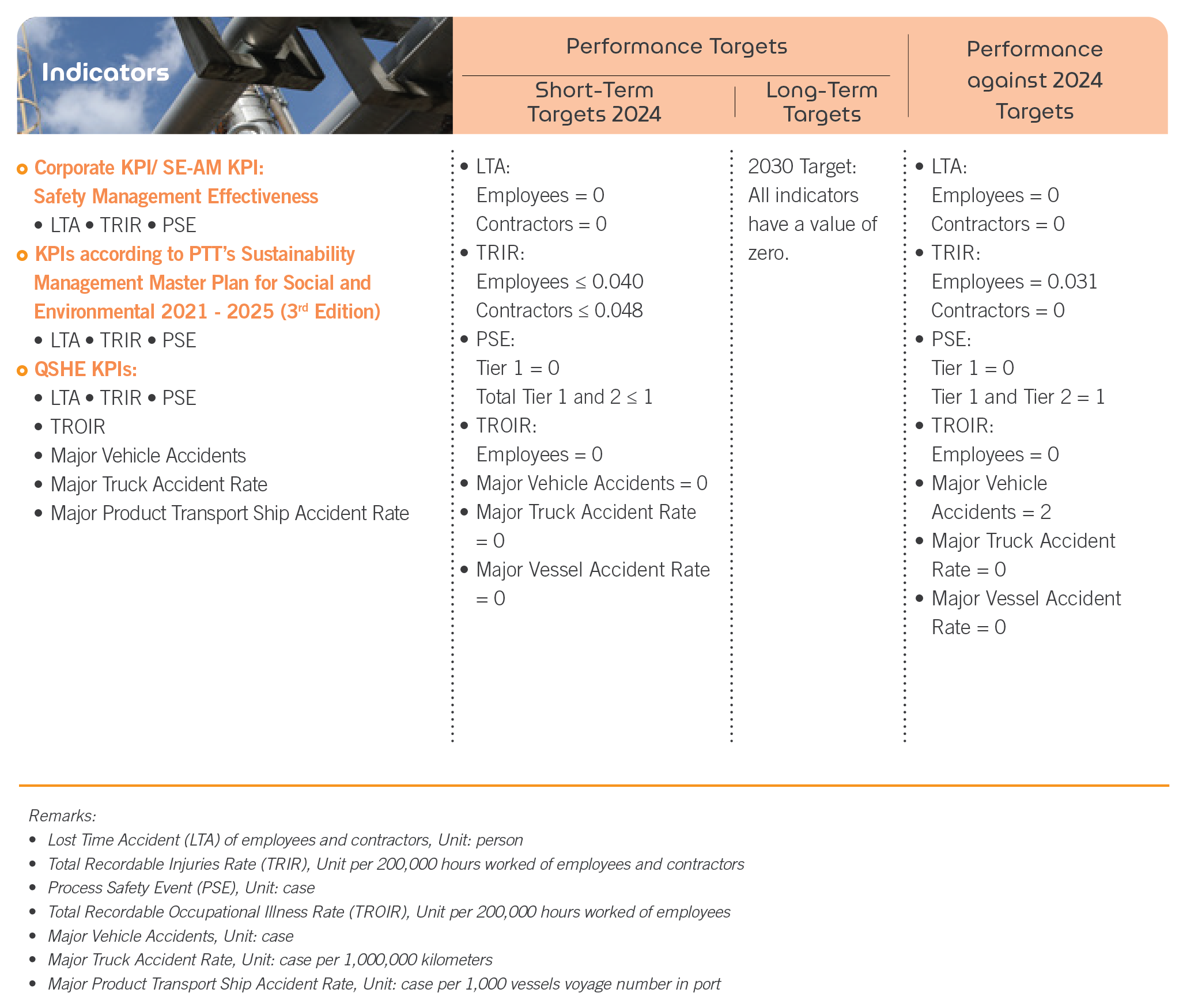

In line with the commitments outlined in the Quality, Security, Safety, Occupational Health, and Environment (QSHE) policy, PTT has established annual QSHE operational targets that are aligned with the PTT’s Sustainability Management Master Plan. These targets aim to transform PTT into a Zero Accident organization by 2030. The key performance indicators (KPIs) for achieving this objective include:

- Lost Time Accident (LTA) of employees and contractors, Unit: person

- Total Recordable Injuries Rate (TRIR), Unit per 200,000 hours worked of employees and contractors

- Process Safety Event (PSE), Unit: case

- Total Recordable Occupational Illness Rate (TROIR), Unit per 200,000 hours worked of employees

- Major Vehicle Accidents, Unit: case

- Major Truck Accident Rate, Unit: case per 1,000,000 kilometers

- Major Product Transport Ship Accident Rate, Unit: case per 1,000 vessels voyage number in port

Additionally, performance indicators are set at various levels to assess the performance of business unit managers. These are then cascaded down into specific departmental targets within each business unit, reflecting the management effectiveness of each unit. Furthermore, PTT Group companies are encouraged to adapt and set targets based on their specific organizational contexts.

Material Topic Management

|

Safety, Occupational Health, and Environmental Targets for the PTT Group

Annual QSHE Operational Targets for the PTT Group in 2025

Key Performance

Personal Safety Management GRI 403-2, GRI 403-5

To control, prevent, and reduce the risks of accidents that directly impact PTT employees and contractors, PTT places a high priority on enhancing its safety, occupational health, and work environment management systems. This also includes fostering a robust safety culture throughout the organization, with a focus on employee and contractor engagement to promote safety awareness and behaviors both during and outside of working hours. Key actions include:

- Establishing comprehensive risk management and control processes for safety, occupational health, and work environment. This encompasses hazard identification, risk assessment, the development of risk control measures, and the implementation of mitigation strategies. These processes are formalized into operational procedures, work practices, and standards that meet international practices.

- Promoting SSHE culture development. A clear and structured process has been developed for cultivating a strong SSHE culture within the organization. Periodic surveys are conducted to evaluate the level of SSHE culture, with the results used to continuously refine and enhance operations.

- Developing video materials and brochures on PTT’s basic safety rules (PTT Life Saving Rules). This includes a review of the operational procedures aligned with PTT's Basic Safety Rules to ensure effective communication and understanding among employees and contractors. Training sessions are organized to promote safe working practices, reduce risks, and prevent accidents and injuries. Special focus is placed on controlling on-site operations, including key processes such as work permits, energy isolation, confined space work, working at heights, use of personal protective equipment (PPE), lifting and handling of objects, and chemical management. Furthermore, employees and contractors are granted theRight to Refuse Work if they find tasks unsafe, with no repercussions. Employees are also given Stop Work Authority to halt any work that may present a safety risk.

- Implementing an incident and non-compliance reporting system. A robust system has been established for employees to report incidents, accidents, near misses, substandard practices or conditions, and any violations of legal requirements, regulations, or operational procedures. The ongoing collection and analysis of this data enable the identification of corrective measures and the development of systematic strategies to control and mitigate risks.

- Providing mandatory and need-based safety training. PTT offers safety training, both mandated by law and based on specific training needs, to all employees and contractors.

- Continuously promoting and developing a safety culture. PTT has launched the Incident and Injury Free (IIF) program at the Rayong and Khanom Natural Gas Separation Plants, focusing on integrating the IIF 5-Step problem-solving process: planning, risk assessment, employee engagement, skill-building, and sustainable implementation. This initiative has been expanded to the Natural Gas Pipeline Division, further reinforcing safety awareness and behaviors. All operational areas are required to enhance safety through Small Group Activities (SGA), which has led to an improvement in the safety culture score from 4.36 to 4.49 (out of 5) and a record of zero severe accidents. Additionally, training has been provided to reinforce safety knowledge and behavior among workers at 9 major gas distribution stations (Mother Stations), with a total of 234 participants. PTT is committed to continually improving and expanding the safety culture across the organization

Occupational Health and Working Environment Management

In managing occupational health and the working environment, PTT has developed the PTT Group Occupational Health Management System and formulated the PTT Group Occupational Health Management System Guideline. These frameworks are in compliance with legal requirements, best practices, and international standards. Key initiatives include:

- Engaging Occupational Medicine Specialists to review and update the Health Risk Assessment (HRA) process, ensuring it comprehensively addresses all major hazards such as physical, chemical, and biological threats. This includes environmental assessments, health screening programs, sampling methods, and sample handling procedures. Additionally, control measures are implemented to mitigate health risks, with mandatory annual occupational health check-ups for all employees.

- Providing Specialized Occupational Health and Safety Training to employees, which includes: Hearing Conservation Programs to educate employees on preventing hearing damage caused by workplace noise exposure, Ergonomics Training for employees in office environments and operational areas, focusing on computer usage and manual material handling. These training sessions are designed to identify and address ergonomic issues, and operational guidelines are established to align with international ergonomic standards.

- Developing and Updating Operational Guidelines for occupational health, including ergonomics for computer work, manual material handling, and medical emergency response procedures. These guidelines aim to enhance the overall management of occupational health within PTT and its subsidiaries, aligned with the Health Performance Indicators (HPI) as per IOGP standards.

Process Safety Management (PSM)GRI 403-2, 403-7

Accidents within the production process can cause significant damage to life, property, and the environment, with far-reaching effects on stakeholders across the entire supply chain. To mitigate these risks, the PTT Group places a strong emphasis on preventing major incidents such as fires, explosions, or the release of hazardous chemicals into the environment. This is achieved through the implementation of a robust “Process Safety Management (PSM)” system across key operational areas. The PSM system ensures that production processes and plant construction are designed and built in accordance with sound engineering principles and international standards. Employees are trained to operate machinery safely according to established operational manuals, while machinery and equipment are regularly maintained and inspected to meet international standards.

PTT Group has established both leading and lagging indicators for process safety, following internationally recognized standards such as API RP 754. These indicators are incorporated into the Company’s annual QSHE targets. Lagging indicators, such as Process Safety Events (Tier 1 and 2), are consistently monitored and reported. This allows for the timely implementation of corrective and preventive measures to address and minimize the risks of production-related incidents, ensuring a proactive approach to process safety.

PTT Group has been applying Bow Tie Analysis techniques and Barrier Validation for Major Accident Events (MAE) since 2019 to systematically analyze and manage process safety risks. This is aimed at preventing and controlling major accidents within operational areas. The Barrier Validation process ensures that the control measures for MAE in the operational risk management system are both effective and in optimal condition, ready for deployment. These control measures include both equipment barriers and human barriers. Should any deficiencies be found in these control measures, they are promptly addressed and corrected to restore their full functionality. Effective and operational control measures for MAE play a crucial role in preventing severe accidents, minimizing production downtime, and ensuring the continuity of business operations. Moreover, these measures help reduce potential impacts on surrounding communities and the environment. In 2024, the PTT Group expanded the application of Bow Tie Analysis to two additional operational areas: the Wangnoi Compressor Station (WCS) and the Sriracha Oil Depot. As a result, all high-risk operational areas across PTT now fully implement Bow Tie Analysis, ensuring comprehensive risk management. The next phase of this initiative involves reviewing and updating the risk data to ensure it remains current, while maintaining the readiness of control measures for ongoing effectiveness. In addition, Barrier Validation was extended to the Ratchaburi Compressor Station (RCS) in 2024. This essential process ensures the thorough verification of both equipment and human control measures, while also promoting the continuous improvement and elevation of process safety standards across PTT and its subsidiaries. These efforts significantly contribute to the prevention of severe accidents, such as fires, explosions, and hazardous chemical leaks. PTT organized workshops to share knowledge and best practices among companies, ensuring the effective implementation and elevation of process safety standards throughout PTT and PTT Group's operational areas.

Additionally, PTT has expanded its Asset Integrity assessments within its operational areas under the PTT Safety Risk Assessment and Assurance program in 2024. This extension covers an additional nine operational areas, helping to further raise operational safety standards across the organization.

Lessons Learned from Major Accident in 2024 |

|||

|

Incident Details: |

|||

Security Management

PTT has established security management standards for the PTT Group, along with risk assessment guidelines to evaluate security threats across the organization. PTT’s security risk assessment approach is based on analyzing the types of threats, motivations, and vulnerabilities to assess the security risks specific to each operational site. The results of this analysis are then used to develop tailored security management measures and ensure ongoing performance monitoring. The Company has also developed procedures for safeguarding personnel and assets, ensuring a consistent and unified approach to security across all operational areas of PTT and the PTT Group. These guidelines are regularly reviewed to stay aligned with changing circumstances and emerging risks. PTT has established clear guidelines, standards, and operational procedures that align with human rights principles to effectively manage security personnel and security forces. These frameworks are designed to ensure that security operations are conducted responsibly and ethically. In developing these guidelines, PTT has studied and referenced the Voluntary Principles on Security and Human Rights, an internationally recognized framework that promotes respect for human rights while maintaining the safety and security of operations. Additionally, PTT collaborates with a network of government agencies, state enterprises, and private sector partners to enhance intelligence operations and ensure swift assistance during emergencies. Regular security and emergency response drills are conducted across the PTT Group’s operational sites, ensuring preparedness and the ability to manage emergencies in a systematic and efficient manner.

PTT places significant emphasis on enhancing its security management capabilities, focusing on three key areas: building personnel competencies, refining operational protocols, and integrating innovative security technologies into operations.

Aware of the potential human rights risks associated with security operations, PTT has clearly defined measures to respect human rights within its Quality, Security, Safety, Occupational Health, and Environment (QSHE) policy. This policy ensures the protection of life, property, and sensitive organizational data. It also mandates that security personnel undergo training in self-defense, personal search techniques, and other related skills. Furthermore, PTT conducts thorough evaluations of security personnel to ensure they understand their roles and responsibilities and operate without infringing on individuals' rights. These policies extend to all security service providers across PTT’s operational areas, with mandatory compliance audits conducted every three years. In response to increasing threats, PTT has also developed a collaborative network for intelligence sharing, allowing for rapid threat assessments. The Company has conducted threat evaluations for PTT and its subsidiaries in three high-risk areas as follows:

1. Southern Region: The three southern border provinces.

|

|

2. Western Region: Specifically in the Thai-Myanmar border area.

|

|

3. Eastern Region: Chonburi Province and Rayong Province.

|

|

In collaboration with external agencies, PTT, together with the National Security Council and its partner networks, organizes the Critical Infrastructure Security (CI-SEC) Academic Conference. This event is designed to strengthen and promote the security of the nation’s critical infrastructure, fostering resilience and advancing best practices in infrastructure protection.

|

Car and Product Transportation Safety Management

PTT is dedicated to enhancing the safety management system for vehicle use and product transportation, striving towards a zero-accident target across all transportation processes, including road, rail, and maritime transport. The Company has undertaken the following initiatives:

| Vehicle Safety Management | Stakeholders: Management, Employees, and Contractors, including Vehicle Drivers. |

|

|

| Product transportation by Road | Stakeholders: Transporting Contractors |

|

|

| Product transportation by Rail | Stakeholders: State Railway of Thailand (SRT) |

|

|

| Marine Product Transportation | Stakeholders: Shipping Contractors |

|

|

| Community Road Safety | Stakeholders: Local Residents in Rayong Province |

|

In 2024, PTT, in collaboration with both public and private sectors in Rayong Province, launched the "Safe Driving for a Better Life" initiative to promote road safety among schools and communities in Rayong. The project comprised two key activities:

|

|

Lesson Learned from Major Accidents in 2024 |

|||

|

Incident Details: |

|||

Emergency and Crisis Management SDGs 3.6

PTT's approach to emergency and crisis management at each operational site includes developing comprehensive emergency response plans, ensuring the local communities are well-informed about procedures, including evacuation protocols. Every year, all operational sites conduct emergency and evacuation drills, actively involving the local communities in the exercises, and allowing them to observe and participate. In 2024, PTT revised the PTT Group Emergency & Crisis Management Guideline to incorporate the Incident Command System (ICS). This integration aims to enhance emergency response capabilities and align PTT’s operations with the National Disaster Prevention and Mitigation Plan of 2021–2027. It ensures effective coordination and information-sharing with relevant government agencies, optimizing emergency management systems for maximum efficiency. In 2024, PTT also organized a province-wide emergency and crisis management drill in collaboration with the Department of Disaster Prevention and Mitigation (DDPM) and other local government agencies in Nakhon Nayok Province. The aim was to ensure that executives and all relevant departments understood their roles and responsibilities, and could effectively integrate emergency and crisis management processes in a systematic and efficient manner to ensure business continuity. The drill simulated a medium-level disaster response (Level 2) along the natural gas pipeline route in Nakhon Nayok Province, specifically focusing on the 42-inch Rayong-Kaeng Khoi natural gas pipeline (Phase 4) in Phrommani Subdistrict, Mueang District, Nakhon Nayok Province. Key participants in the exercise included the Governor of Nakhon Nayok, the Nakhon Nayok Disaster Prevention and Mitigation Office, the Provincial Public Health Office, the Provincial Labor Welfare and Protection Office, the Provincial Energy Office, the Provincial Natural Resources and Environment Office, the Provincial Public Relations Office, the Provincial Electricity Authority, Mueang Nakhon Nayok District, Nakhon Nayok Hospital, Nakhon Nayok Police Station, Phrommani Subdistrict Administrative Organization (SAO), local community representatives, and PTT.

Business Continuity Management SDGs 3.6

PTT continually reviews, updates, and enhances its Business Continuity Management (BCM) system, ensuring that contingency plans for securing backup resources in emergencies are in place while also conducting regular business continuity drills. In 2024, a simulated emergency exercise was carried out to address a scenario where the LNG Map Ta Phut Terminal 1 (LMPT1) of PTTLNG was deliberately set on fire, and the natural gas pipeline was sabotaged, causing widespread disruption to the natural gas supply in the eastern region, impacting more than one source. The drill was overseen by the CEO and President, with senior management from the Crisis Management Center (CMC) actively participating. The exercise was coordinated with the emergency management center of the business group via a video conferencing system. Additionally, PTT continues to uphold its ISO 22301 certification for business continuity, which includes managing the Company's critical infrastructure systems. This certification is rigorously maintained and regularly audited by the ISO Certification Body.

Employee Health PromotionGRI403-6

PTT provides comprehensive healthcare services to its employees and their families, offering medical treatment at no cost for non-work-related health issues. PTT prioritizes employee health and well-being as part of its commitment to global health challenges. This initiative aligns with UN Sustainable Development Goal (SDG) 3.3, which aims to combat major diseases that remain leading causes of mortality worldwide, including HIV, tuberculosis, and malaria. PTT ensures that all operational areas adhere to these standards, even though current locations are situated outside high-risk zones for these diseases. To safeguard employees, PTT provides comprehensive healthcare benefits and implements continuous awareness programs to promote preventive measures and early detection. These efforts reflect PTT’s dedication to creating a safe and healthy work environment across all operations. Employees and their families are also eligible for healthcare services at external medical facilities, as defined in PTT’s benefits framework. Moreover, PTT analyzes the results of annual health check-ups and medical treatment data to design and implement continuous health promotion initiatives. These programs are aimed at maintaining and improving the physical and mental well-being of employees and contractors. Some of these initiatives include the Fight Fat Fun exercising program, the GSP Anti Office Syndrome program at the natural gas separation plant, and regular health communication through internal emails and newsletters. All health-related data is stored securely in a Personal Health Database, in compliance with applicable data protection laws, PTT’s internal policies, and best practices for managing personal information. In this regard, employees can access their health information through the Company’s intranet.

Collaboration with Partners and Networks

Road Safety Partnership Program with Public and Private Sectors

To reduce road accidents in Thailand, PTT has forged partnerships with key stakeholders from both the public and private sectors, including the Department of Disaster Prevention and Mitigation (DDPM), the Department of Land Transport, the Highway Department, Road Accident Victims Protection Co., Ltd., the Provincial Public Health Office, PTT Group. Together, they have launched the "Safe Driving for a Better Life" initiative in Rayong Province, aimed at promoting road safety awareness and instilling a sense of responsibility among individuals, road users, and the local community. In 2024, PTT, in collaboration with both public and private sector partners in Rayong, organized a series of activities for schools and communities in the area, as follows:

- “New Generation Students: Driving Licenses” Initiative: In partnership with the Department of Land Transport and NPC Safety and Environmental Service Co., Ltd., this initiative focused on providing training on safe motorcycle riding practices. The program aimed to foster understanding of safe driving principles and encourage students to obtain their motorcycle licenses upon completion of the training. In 2024, PTT organized sessions at two schools, with 306 students successfully completing the training and obtaining their motorcycle licenses.

- “Good Drive Challenge Clip Contest”: This contest, conducted in collaboration with various stakeholders, encouraged youth and the public in Rayong to participate in creative efforts to raise awareness about road safety and accident prevention. The competition invited participants to submit video clips under the theme “Safe Driving for a Better Life: Road Safety is a Shared Responsibility.” The goal was to change attitudes and behaviors towards safe driving. In 2024, 47 teams from 11 educational institutions in Rayong, spanning primary, secondary, vocational, and university levels, participated in the contest. The five winning entries were used for public awareness campaigns, promoting road safety and accident reduction through the project's social media platforms.

Security Network

In 2024, PTT, in collaboration with the National Security Council, the National Intelligence Agency, the Special Branch Bureau, Chulalongkorn University, and the Mass Rapid Transit Authority of Thailand (MRTA), co-hosted the "CI-SEC 2024: Annual Academic Conference on Security Crisis Management" from August 28-29, 2024, at the IMPACT Exhibition and Convention Center, Muang Thong Thani. This conference aimed to foster the development of a robust network for exchanging information, knowledge, and best practices in security management, ensuring better integration between government security agencies, state enterprises, research institutions, innovation bodies, and relevant academic organizations. Attendees included representatives from the PTT Group, state enterprises, academic institutions, international organizations, as well as strategic-level security agencies, intelligence services, and policy-making bodies involved in national security.

Additionally, during the period of 2023-2024, when instances of unrest occurred in various regions, PTT proactively initiated the creation of a security intelligence network within the PTT Group. This network serves as an essential channel for facilitating the exchange of critical information with security agencies and for coordinating intelligence activities. This initiative is aimed at developing strategic frameworks and operational guidelines to prevent and respond to security threats, particularly unrest, in collaboration with relevant authorities. Furthermore, recognizing the emerging risks posed by technological advancements, particularly the rise of unmanned vehicles (drones), PTT established a comprehensive framework to manage these potential threats. This initiative was carried out in collaboration with experts from the public sector, state enterprises, and private industry to share insights and formulate strategies for effectively managing risks associated with unmanned vehicles. Through this collaboration, PTT aims to ensure its preparedness in effectively handling and mitigating the security challenges posed by this new and evolving threat.

Future Plans

PTT is dedicated to managing safety, occupational health, and environmental conditions in the workplace, with the ultimate goal of becoming an organization that achieves zero accidents. This commitment is aimed at building trust and confidence among all stakeholders. The focus is on fostering active participation in safety from both employees and contractors. In 2025, key initiatives include promoting a safety culture in the natural gas for vehicles, particularly with a focus on vehicle safety operations, expanding the use of Bow Tie Analysis and Barrier Validation techniques, along with implementing process safety management across PTT’s operational sites, introducing a Health Risk Assessment system via a web-based platform, launching the Defensive Driving Auto-Assessment System (DAS).